5000㎡ plant area

5000㎡ plant area

1 million+ pieces shipped

1 million+ pieces shipped

24-hour service

24 hour service for 10 senior teams務(wù)

Reliable quality

13 years of focus on the magnetic

Affordable price

Factory direct sales at affordable prices

- Focusing on magnets for 13 years, our own factory can process various types of magnets -

Dongguan Weida Magnetic Industry Co., Ltd.

Phone: 0769-22174472

Contact: Mr. Hu 13688952526

Email: hw@zlwdcy.com

Website: yoyolube.cn

Address: First industrial zone, Tiantou village, Hengli Town, Dongguan City

- Experience in comprehensive technical and service capabilities, delivery of each batch of magnet products -

-

01

Technical

-

02

Capacity

-

03

Quality Control

-

04

Intimate Service

Technical precipitation

Irregular magnet: Complex shape, performance, and plating can be customized

Performance includes: N33-N52.33M-52M, 33H-52H, 35SH-48Sh33UH-45UH, 33EH-42EH, 33AH-40AH

Coatings include: galvanized (blue white), galvanized (colored) nickel+copper+nickel, nickel+copper+nickel+tin, chemical nickel, epoxy, passivation, aluminum, aluminum+epoxyZinc aluminum, EverluberTeflon, Perrin coating

Multipole magnet: The multi-pole mold is complete, which can achieve efficient samples and save time and cost

Specifications include: circular diameter 1mm to 300mm, thickness 0.2mm-100mm

Production Capacity

Having full production and processing capabilities

Equipped with more than 200 sets of rear production equipment such as inner circle slicing machine, multi wire cutting machine, high-precision automatic punching machine, automatic drilling machine, high-precision grinding machine, small-sized cylindrical production equipment, and irregular grinding equipmentIt can meet the machining requirements of various products, achieve a one-stop process, and improve production efficiency

Strict Quality Control

A comprehensive quality management system with finished product inspection departments and sequin inspection departments

Equipped with performance tester, salt spray tester, coating thickness tester, visual inspection machine, film selection machine, projector, magnetic flux meter, automatic magnetization machine, automatic labeling machine

Meet the needs of various product testing, provide high-quality products, and provide customized services for various products

Intimate Service

Set up product process planning to help customized customers find better combination solutions for product process and cost control

Customers need to develop new products in a one-stop process, with flexible order scheduling and fast product delivery time to help accelerate the customer's research and development cycle

Dedicated personnel are responsible for tracking and managing the order process, connecting customers to shipment delivery and post service

Can answer various difficult points in the customized development and application of magnets for customers and provide optimization suggestions

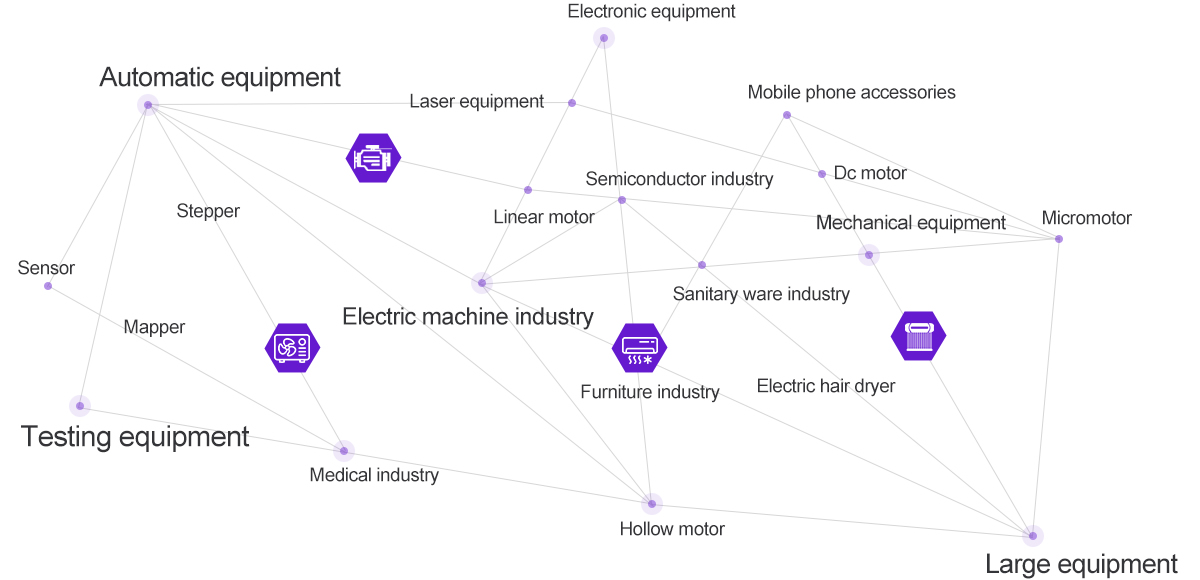

Partner trust Weida unremitting power

- Full range of technical experience to deliver each batch of magnet products -

Customized service process

- Collaboration at each stage for efficient delivery -

01

Consulting

Communication needs

02

Evaluate

Sample quotation

03

Confirm

Confirm Customization

04

Quotation

Signing contract

05

Production

Processing and production

06

Quality

Quality inspection control

07

Delivery

After-sale service

136-8895-2526

136-8895-2526

Dongguan Weida Magnetic Industry Co., Ltd., No. 6 Longxing Road, Hengli Town, Dongguan City, Guangdong Province

Dongguan Weida Magnetic Industry Co., Ltd., No. 6 Longxing Road, Hengli Town, Dongguan City, Guangdong Province